|

General Characteristics

Novel, electrically-conductive thermoplastic polyolefin-based materials (namely, with a polyethylene, polypropylene, or mixed, matrix) containing a modest weight fraction of dispersed metal powder, for the following broad range of technical uses:

The compositions and related technical uses for super-fast microwave (or combined microwave + infrared) after-processing outlined hereinabove have been disclosed and claimed by the international patent application WO-2004-048463 (A1) (June 10, 2004; to F. Parodi), and covered by the Italian Patent IT-1,334,163 (May 24, 2006; to F. Parodi) [published as Ital. Pat. Appl. ITGE20020104 (A1) (May 23, 2004)]..

1. Constitutive Characteristics of the Novel Materials The novel materials include:

The proprietary system of additives C simultaneously acts within the thermoplastic composition as:

2. Super-accelerated Microwave Processibility of the Novel Materials 2.1. Microwave Heatability Even under mild microwave treatment conditions (at the std. UHF ISM frequency of 2450 MHz) in ambient air at room temperature in low-power, domestic microwave ovens (and hence without any processing optimization devices industrial UHF ovens are commonly equipped with), the novel materials exhibit a particularly strong microwave heatability. Under these microwave treatment conditions, in fact, they show average heating rates of 2 ÷ 5 °C/sec, depending on the percentage of the metal powder (or metal powder system) and the proprietary system of additives C added to the polyolefin matrix. Such heating rates are 25-40% higher than those displayed by the equivalent, conventional polyolefin-metal powder compositions, under the same UHF treatment conditions. The diagrams of Figures 1 and 2 show the UHF heating curves under perfectly identical conditions for two innovative thermoplastic materials, of LDPE-aluminum powder and polypropylene-aluminum powder type, respectively, as compared to equivalent, conventional compositions made of the same polymeric matrices with an identical amount of the same aluminum powder. Figure 1 - Typical UHF heating curves (at the std. ISM frequency of 2450 MHz, under a constant UHF power = 800 W) for two LDPE–Aluminum powder compositions: a) novel; b) conventional (containing the same % of the same metal powder). Test pieces: equilateral cylinders (Ø = 38 mm); values of the core temperature.

Figure 2 - Typical UHF heating curves (at the std. ISM frequency of 2450 MHz, under a constant UHF power = 800 W) for two Polypropylene–Aluminum powder compositions: a) novel; b) conventional (containing the same % of the same metal powder). Test pieces: equilateral cylinders (Ø = 38 mm); values of the core temperature.

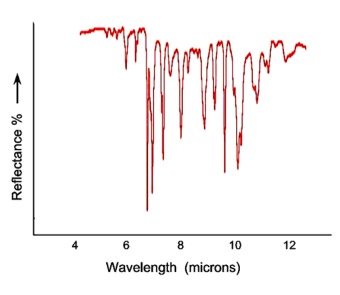

2.2 Combined Microwave + Infrared Heatability Thanks to the proprietary system of additives C, the surface layers (or, more properly, the outer portions) of semi-finished or finished articles made of the novel metal-filled polymeric materials are advantageously much more rapidly heatable by infrared irradiation than those of the corresponding conventional compositions. Indeed, conventional metal-filled polyolefins are inherently characterized by a particularly high reflectivity and emissivity of infrared radiation, being imparted by common, glittering aluminum, brass or bronze powders. The infrared reflectance spectrum shown in Figure 3 exemplifies the absorption capacities of the radiant energy emitted by "soft" infrared radiators (i.e. infrared radiators at temperatures between 100 and 250°C, whose maximum emission intensity is located at wavelengths comprised in the 8 ÷ 5.5 µm interval, such as the warm walls of the UHF oven itself, or also hot bodies or adjacent portions of the same material undergoing UHF heating), imparted by the system of additives C to the novel polyolefin materials.

Figure 3 - FT-IR infrared reflecance spectrum (ATR technique) for a typical LDPE polyethylene–system of additives "C", according to the international patent application WO-2004-048463 A1.

The temperature-vs-time curves shown in Figure 4 for the core and the surface of cylindrical specimens exemplify the fast internal heatability under microwave irradiation, and the even faster and uniform heatability (of both the bulk and the surface) under combined microwave + infrared irradiation, of finished or semi-finished pieces made of thermoplastic compositions of the novel type, with a polypropylene matrix.

|

|

|

|

|

|

Figure 4 - UHF e UHF + IR heating curves (under constant irradiation power) of equilateral cylindrical test pieces (Ø = 38 mm) made of a novel, thermoplastic Polypropylene–Aluminum powder composition: values of the core and upper surface (IR-irradiated) temperature.

3. Electrical Conductivity 3.1 Electrical Surface Conductivity data collection in progress

3.2 Electrical Volume Conductivity data collection in progress

4. Other Physical Properties of the Novel Materials 4.1 Density: density at 20°C comprised in the 0.96-1.05 g/cm3 range, depending on the type of polyolefin material (LDPE, LLDPE, PP, etc.), and the percentage of both the metal powder and the proprietary system of additives "C". 4.2 Color. The novel materials display a light-grey or a golden-grey color, with a moderate metallic luster, similarly to all polymeric materials and coatings containing aluminum, brass and/or bronze powders. However, by virtue of the relatively low volume fraction of metal powders being present, they are susceptible, similarly to common metallic paints on the market, to be pigmented in a broad variety of colors by addition of pigment amounts comparatively slightly higher than ordinarily used. Such pigment additions do not attenuate (on the contrary, often enhance) the electrical conductivity, the electromagnetic absorption capacities, as well as the microwave and infrared heatability, of the novel materials.

|

|

____________________________________________________________________________

|

© Dr. Fabrizio Parodi - 2000-2015 |