|

|

Dr. F. Parodi - Industrial R&D Expert Expertise & Know-How: Microwave & RF Chemistry and Processing |

|

|

Dr. F. Parodi - Industrial R&D Expert Expertise & Know-How: Microwave & RF Chemistry and Processing |

| polymer & organic chemistry | | microwave & RF | |

________________________________________________________

|

Advanced Solutions for Microwave & Radio Frequency Processing and Chemical Syntheses Dr. F. Parodi's patents, publications, lectures, seminars and technical reports on Microwave & Radio Frequency physics, chemistry & processing > complete list < _______________________________________ |

|

Microwave Chemicals: Specialty Additives for the Accelerated Microwave and Radio Frequency Processing of Rubbers, Plastics, Resins and Composite Materials |

|||

|

Novel and proprietary additives and systems of additives for the enhancement of the microwave (UHF) and radio frequency (HF) heatability and UHF/HF processability of the greatest variety of plastics, rubbers and resins, or even enabling a fair-to-nice electromagnetic heatability and processability of microwave and RF-transparent polymeric materials: homo- and co-polyolefin plastics and rubbers [polyethylene, polypropylene, ethylene-propylene copolymers, EP(D)M rubbers, etc.]; natural rubber and synthetic polyisoprenes, butyl rubber, cyclopentadiene-based plastics and adhesives, diene and diene-styrene rubbers (such as polybutadienes, SBR and SEBS), etc. Attainable microwave and/or radio frequency-absorbing plastics, rubbers and resins are suitable as convenient electromagnetic shielding materials. Proprietary products of Dr F. Parodi.

|

|

||

|

|

|||

|

|

|||

|

Smart Microwave Catalysts & Reaction Redesign for Microwave-Enhanced Chemistry |

|||

|

|

||

|

|||

|

|||

|

|||

|

|

||

|

Co-design of Advanced Microwave Power Irradiation Systems for Enhanced Chemical Syntheses |

|||

|

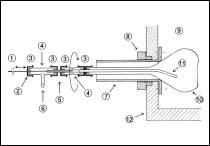

The subject, fully computer-contolled systems are being co-designed, and exactly customized according to the specific needs, in conjunction with leading constructors of microwave and RF equipment & instrumentations. These unique microwave power irradiation systems afford exceptionally high electromagnetic field energy densities, thus multiplying the effects of UHF (or SHF) irradiation on reaction kinetics, mechanism and thermodynamics (in either the presence or absence of the specialty microwave sensitizers or catalysts proposed above). The new devices are designed for organic syntheses carried out in a flowing solution or suspension, in either organic or aqueous media, with excellent temperature control. Continuous-flow processes and re-circulation of liquid reacting mixtures are both considered. The automatic and progressive, electronic retuning of the irradiation frequency to the reacting system, and a precise, continual adjustment of the irradiation power ensure efficiency levels unrivaled by any other microwave heating equipment for chemical syntheses to date proposed. Proprietary, perfectly microwave-transparent, very high-temperature & pressure-resistant, thermal shock-insensitive, and absolutely chemically inert cylindrical ducts of the flowing reacting mixtures are designed and fabricated as key-components of the novel devices. In its standard configuration, any apparatus is already suitable for both research and process development, and industrial production of value-added chemicals (catalysts, specialty additives and pharmaceuticals). |

|

||

|

|

|||

________________________

|

|

Novel polyethylene and polypropylene thermoplastic compositions designed for a range of accelerated hot manufacturing operations on polymeric preforms, semifinished articles, parts or components by means of mechanical stresses (e.g. stretching, curving, folding, die casting, welding, etc.) applied under super-rapid and penetrating heating by microwave irradiation, or combined microwave + infrared irradiation, in conventional, tunnel or closed-chamber, industrial UHF devices : World Pat. Appl. WO-2004-048463-A1 (Jun. 10, 2004; to F. Parodi) [ ABSTRACT ] [ see Technical Note #4 ] |

back to index: "Expertise & Know-How"

| polymer & organic chemistry | | microwave & RF | |

|

© Dr. Fabrizio Parodi - 2000-2015 |